Been making some gradual progress as time allows, thought I'd report in the latest.

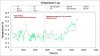

I have 3 of the TSIC 506F sensors now, to make sure the results are good and repeatable with a reasonable effort. All three report in values in close tolerance of each other so this combo will provide the reference to calibrate other sensors by.

I made use of the spare Arduino for the moment to rig these three up.

These sensors were about £6.50 ea

from Farnell

The Swiss are pretty well known for accuracy, and these little gems exhibit exactly that. They are good low power (35uA) sensors giving simple temperature measurements (unlike TSYS01 needing some hefty maths to get the reading) and outstanding 0.1deg c absolute accuracy. The resolution is 0.034 deg.

Between the three sensors I have, the readings are within 0.05deg of each other

The sensors have some pretty nice features, high precision on chip measurement, built in EEPROM which stores the factory calibration giving a result better than F0.1 Platinum sensors AND the accuracy is unaffected by long extended cables (>10m)

I was able to figure how well they work but the arduino library available is made to keep switching those sensors on and off to get readings. I want to leave them in ON mode and read their 10Hz output instead, which I adjusted the stock library to kind of do but with messed up measurement on some reads. so Im having to meddle with creating a new Arduino library to do it reliably.

Instructions for putting together a TSIC 506F based probe ;

1. First thing is acquire some decent cable, shielded if its going to be a reasonable run, few feet or more. I ordered in a bunch of 5M USB extension leads for about 1.50 ea off eBay. Worked out nice for some flexy shielded four core stuff to use for sensor probe leads.

2. Strip one end back, you'll need three wires for the TSIC 506F , 5V power, Gnd and Signal. In my case I terminated the end with three pin header to attach to an Arduino IO board.

3. The sensor end. Take the TSIC 506F and cut back the pins about 5mm since they are very long. Get a 100nF cap and solder it across the power/gnd pins, the two outer pins. Connect the 5V, gnd and signal lines like in the pictures. Note I soldered directly the green (signal) wire and heatshrunk it prior to soldering the cap and finally the 5V and Gnd pins.

4. Heatshrink over the assembly

5. Your good to go. This can now be rigged up to Arduino . The sensor is sensitive to noise on the 5V line, so put a nice big cap between the arduino's 5V rail and ground, 100uF I used hold it smooth. Head over to

http://playground.arduino.cc/Code/Tsic and get the library (version tuned for 506F)and go from the example sketch.

Now you will have an accurate fix on temperature. You can use this to figure out what offset you need with cheaper sensors like thermistors etc, ie calibrate them against this reference.

Hope its useful to someone. I will update you guys after I get the new library working nicely.

:. You are one of my personal heroes here on AFN for attempting something like this.